At Krafter’s, we start our process by feasibility study of each component individually and assembled conditions followed by Flow analysis Report and Design For Manufacturing (DFM) .Â

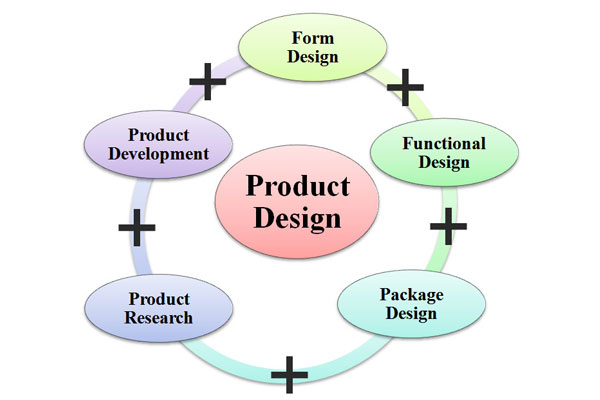

Our 13 step check points on Product Design, ensures that we at Krafter’s, understand in-depth characteristics of each part before start of any actual material cutting, thus avoiding any kind of surprises after 1st trial. The client and Krafter’s will be equipped with what need to be done for the desired outcome. Complete reliance on scientific methods and vast problem solving expertise of founders, throughout their career, has helped them, to build the best quality moulds and tools.Â